PSBO: The gentle giant that protects the sea of Rimini

Focus

Focus

Category Facet

Custom Facet

Search Results

-

Web Content Article · By Antonio Filippone On Jul 21, 2025 4:03 PM

Expanding fibre coverage in industrial areas and boosting data centre services: a growing offering for businesses and individuals.

Innovation Categories: Remote Control -

Web Content Article · By Antonio Filippone On Jul 21, 2025 3:43 PM

A project developed in partnership with Aliplast and Idrotherm 2000 involves the use of recycled plastic to produce pipes for electricity and sewer networks.

Innovation Categories: Regeneration of resources -

Web Content Article · By Antonio Filippone On Jul 21, 2025 3:20 PM

In Bologna, we will build the new SynBioS plant – a cutting-edge solution of international relevance in the field of clean energy – to convert renewable electricity into synthetic natural gas and...

Categoria Progetto: Energy Efficiency Innovation Categories: Energy -

Web Content Article · By Antonio Filippone On Jul 21, 2025 2:47 PM

From carbon footprint monitoring to transforming plastic into an endlessly recyclable resource. This is how, together with Aliplast, we are committing to the transition to a circular economy.

Categoria Progetto: Innovation Innovation Categories: Regeneration of resources -

Web Content Article · By LUCIA ALGISI On Dec 18, 2024 11:20 PM

The connection between the water cycle and agriculture has grown increasingly strong over the years, based on a straightforward principle

Categoria Progetto: Innovation Water Project -

Web Content Article · By LUCIA ALGISI On Nov 29, 2023 2:30 PM

Early warning system with innovative FingerPrint technology to ensure safe water

Categoria Progetto: Innovation Water Project -

Web Content Article · By LUCIA ALGISI On Nov 29, 2023 2:35 PM

Discover the project for “removing and capturing” microcontaminants with recycled materials

Categoria Progetto: Innovation Water Project -

Web Content Article · By LUCIA ALGISI On Nov 29, 2023 12:05 PM

Hera continues experimentation of the innovative, fast and low-cost contactless system that uses space technology to detect water leaks in the network more quickly and productively

cosmicrays Categoria Progetto: Water Project Innovation -

Web Content Article · By LUCIA ALGISI On Nov 29, 2023 12:21 PM

The pilot project involving the installation of Kamstrup meters was carried out in Conselice, near Ravenna, and yielded excellent results. The tests now continue in Modena, covering a larger area

Categoria Progetto: Innovation Water Project -

Web Content Article On Mar 8, 2021 1:42 PM

Smarty, The new line of waste containers smarty.png no

-

Web Content Article On Mar 8, 2021 1:41 PM

Waste-to-energy plants: a resource for the circular economy /-/waste-to-energy-plants-a-resource-for-the-circular-economy waste-to-energy.png no

-

Web Content Article · By Palvi Andrea Tonziello On Aug 4, 2020 5:25 PM

A revolution rooted in the circular economy: thanks to separate waste collection, organic waste is fed into an anaerobic digestion process to produce biogas.

circulareconomy Categoria Progetto: Innovation Heratech Project Innovation Categories: Regeneration of resources -

Web Content Article On Aug 4, 2020 5:20 PM

District heating is already in itself a "sustainable" and environment-friendly solution, because it can guarantee better performance than traditional domestic boilers. In addition, the plant...

Categoria Progetto: Heratech Project Energy Efficiency -

Web Content Article On Aug 4, 2020 5:14 PM

With the Geocall IT system, we have applied the benefits of digitalisation to our emergency response operations, making all relevant information available via smartphone. Find out how we have made...

-

Web Content Article On Aug 4, 2020 5:12 PM

Since 2017, we have been developing a measuring system, conceived by Hera Luce, which analyses the materials used in public lighting. What's the target? Making their life cycle circular, as well.

Categoria Progetto: Energy Efficiency Circular Economy -

Web Content Article On Aug 4, 2020 5:08 PM

Producing electricity and heat from non-reusable waste. How? In a waste-to-energy plant: it's a safe and legally compliant plant and an energy resource for the local area.

Categoria Progetto: Energy Efficiency Circular Economy -

Web Content Article On Aug 4, 2020 5:04 PM

Waste can become sofas, lamps, games, and musical instruments. But even stage sets, art objects and installations. How? We'll tell you about it in this project.

Categoria Progetto: Circular Economy -

Web Content Article On Aug 4, 2020 5:02 PM

Thanks to robotics and artificial intelligence, we can streamline our workflows and enhance the value of people and their intellectual capabilities. With the Robotic & Intelligent Process...

-

Web Content Article · By LUCIA ALGISI On Aug 4, 2020 4:49 PM

Thanks to the Optimised Seawater Protection Plan”, Rimini's beaches will be 100% safe to swim. Discover the most important milestones and works of the project to protect the sea

psbo Categoria Progetto: Heratech Project Circular Economy Water Project -

Web Content Article On Aug 4, 2020 4:39 PM

How do we monitor 6,600 plants and over 67,000 km of networks? With our Forlì Remote Control Technological Hub, which monitors operation in real time to detect failures and malfunctions of...

utility4.0 Categoria Progetto: Innovation

Asset Publisher

Thanks to the Optimised Seawater Protection Plan”, Rimini's beaches will be 100% safe to swim. Discover the most important milestones and works of the project to protect the sea

Keeping the sea clean and ensuring it is safe for swimming is a complex task, but not an impossible one. This is demonstrated by the Rimini Optimised Seawater Protection Plan (PSBO), the largest water sanitation project currently underway in Italy, which we have developed in collaboration with the town’s municipality, with Romagna Acque and Amir. A construction site — or rather, 14 — that is quite literally transforming the face of a town that has been the backdrop to the holidays of millions of Italian and international tourists for over 60 years. With an investment of €270 million, the project will ensure the complete bathing safety of the Rimini coastline, eliminating wastewater from all 11 sea discharges. Restoring clean, healthy and crystal-clear sea to Rimini and the surrounding area is a vital step in enhancing and creating new opportunities for the whole community. Because the sea is not just a key driver of the economy — it is the heart of our identity.

Piazzale Kennedy, where it all began

It was beneath Piazzale Kennedy that the great works to build the gentle giant that protects the sea started. In case of a storm, the wastewater treatment plant is unable to handle such a large volume of both clear and dark waters. To prevent damage to the plant and avoid flooding, these waters are discharged into the sea without treatment. This results in a bathing ban, with an impact on the environment, health and the local economy.

The PSBO prevents this thanks to a system of tanks as large as 20 Olympic swimming pools, located 40 metres below the surface. The first tank, with a capacity of 14,000 cubic metres, collects the initial rainfall, while the second, with a capacity of 25,000 cubic metres, is dedicated to regulating the flow of clean water into the sea. Thanks to a forced ventilation system, which directs the air drawn from the tanks to a treatment system using activated carbon technology, the problem of foul odours can also be permanently solved. Concealing this complex facility with its modern architecture, seamlessly integrated into the urban landscape, is the Piazzale Kennedy viewpoint, which has been open to the public since 2019.

The Santa Giustina treatment plant, the heart of the PSBO

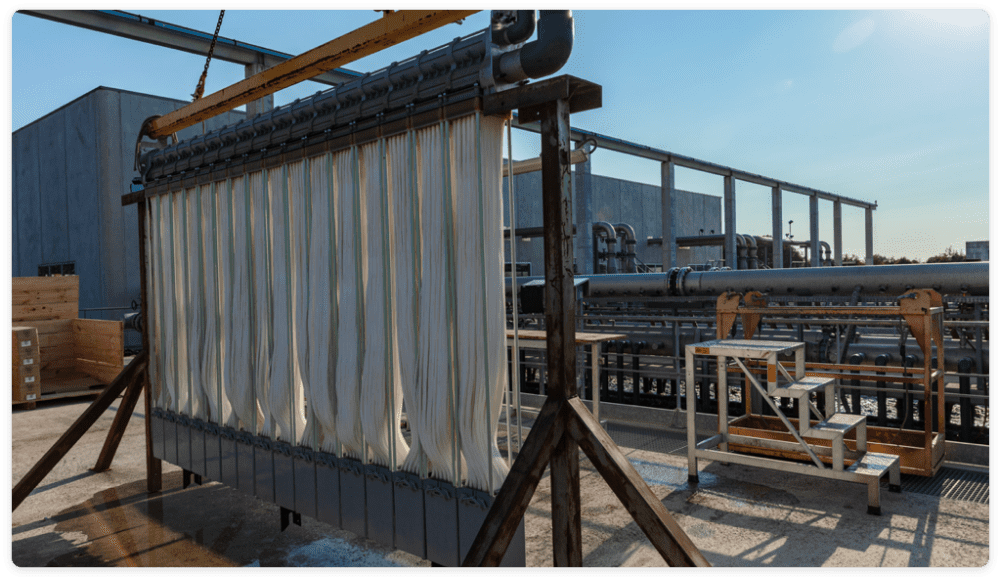

Once the water has been collected in the tanks, a true journey begins beneath Piazzale Kennedy, perhaps the most important of all the activities connected to the PSBO. The tank system is linked to a pumping station with a discharge capacity of 18,000 litres per second: the Santa Giustina treatment plant. This is the heart of Rimini’s gentle giant, which transforms the water, making it, as a famous song says, “clear and blue”. Enhanced with a series of upgrades that have doubled its capacity, the plant can now treat all wastewater, both domestic and industrial, from the Rimini area and the Republic of San Marino, serving 560,000 residents during the summer season. After separating the water from sand and oils and eliminating the sewage sludge using denitrifying bacteria (organisms that feed on the substances contained in the sludge), the treatment plant makes the wastewater clear and clean through microfiltrating membranes, a cutting-edge technology that captures microscopic particles such as viruses and bacteria.

The PSBO's most important works

Let’s revisit the history of this ambitious project. The doubling of the Santa Giustina treatment plant, which began in 2013 and was completed in 2015, marked the true kick-off of the PSBO. Its operation, which is the heart of the entire system, was closely linked to the conversion work at the Marecchiese treatment plant, which serves to regulate the flows directed to Santa Giustina. 2014 marked the beginning of another important milestone: the start of the remodelling of the sewerage system in Rimini, which initially involved the redevelopment of Rimini Isola, and later the separation of the sewerage systems of Rimini Nord. The latter, which is scheduled to be completed in 2026, is a crucial step in the entire project, directly involving residents in the area, who are asked to connect their discharge properly to the new sewerage pipes for wastewater.

At the same time, the North Dorsal project was completed in 2015, connecting the Santa Giustina treatment plant with the Bellaria plant. In 2018, the excavation work (microtunneling) for the South Dorsal was also completed: thanks to a boring machine, it was possible to lay pipes beneath natural elevations or major roads in urban areas without the need for large-scale excavation. Other works, such as the Ausa sewer collector, the Mavone overflow channel and the sewer lift in via Santa Chiara, have significantly reduced the risk of flooding in many areas of the town where this problem is recurring. Additionally, with the project to cover the Ausa Canal, which involves its artificial capping, we have optimised the water flow in the final stretch from the seafront to the sea in case of overflow discharge, creating an attractive pathway between the seafront and Piazzale Kennedy that enhances the nearby beaches.

Two new viewpoints as the PSBO moves south

Starting from 2025, the PSBO in Rimini will enter a new phase with the start of key works and projects. Work will begin to build two retention tanks for rainwater and initial rainfall, which are vital for managing stormwater and preventing flooding. These tanks will be located at Colonnella 2 (Piazzale Arturo Toscanini) and at the Rodella pit in Rivazzurra (Piazzale Artemisia Gentileschi). But the developments don’t end there. Above the tanks, in a fully redeveloped area, two beautiful viewpoints will be built as part of the Parco del Mare. These will offer stunning views of the sea and will integrate seamlessly into the urban environment, following the design lines of the Parco del Mare project.

The results we have achieved

To date, construction works are 90% complete and they have already freed 8,000 metres of coastline from bathing restrictions, a figure that will rise to 12,000 metres upon completion. Through sifting and storage treatments, over 20,000 cubic metres of sand have also been recovered for beach replenishment. This operation, which could be described as a true “nourishment” of the beaches through the addition of new sand, helps counteract coastal erosion, following the principles of the circular economy. These achievements, along with all the other planned interventions, have led the PSBO to be cited in the United Nations report “SDG Industry Matrix: Energy, Natural Resources and Chemicals” (2017) as a best practice related to the sustainable development goals of the 2030 UN Agenda.

Search Bar

Tag Facet

Search Results

Asset Publisher

Creating shared value report 2024

.jpg/5c532605-0938-031b-74ff-89388f7410d3)

.jpg/468d051b-ba80-83a6-359d-7ef55eefd940)

.jpeg/1d0e0770-1094-b22b-fce4-099f27c72978)