HERA's strategy for hydrogen production

HERA's strategy for hydrogen production

- Group

- Investors

- Hera Strategy

- HERA's strategy for hydrogen production

The Hera Group and hydrogen

![]() Hera will reduce emissions by 37% by 2030. This scientifically certified target is one of the most ambitious among companies in Italy and is consistent with the “well below 2 C” scenario, which aims to limit the increase in global temperature to significantly less than 2°C compared to pre-industrial data. Hera’s commitment is not limited to the emissions produced by the Group’s own activities, but also covers those of its customers, related to electricity and gas sales, and its suppliers.

Hera will reduce emissions by 37% by 2030. This scientifically certified target is one of the most ambitious among companies in Italy and is consistent with the “well below 2 C” scenario, which aims to limit the increase in global temperature to significantly less than 2°C compared to pre-industrial data. Hera’s commitment is not limited to the emissions produced by the Group’s own activities, but also covers those of its customers, related to electricity and gas sales, and its suppliers.

The interventions planned include further expansion in district heating, an increased use of electricity from renewable sources and energy upgrading for buildings, but also launching initiatives to develop hydrogen as an energy vector.

Hydrogen at a glance

With its System Integration Strategy, published in July 2020, the European Commission has outlined an innovative path to achieve full decarbonisation of the energy sector by 2050, which aims to overcome the opposition between individual energy supply chains in “silos”, and move towards a system that can make the various infrastructures communicate.

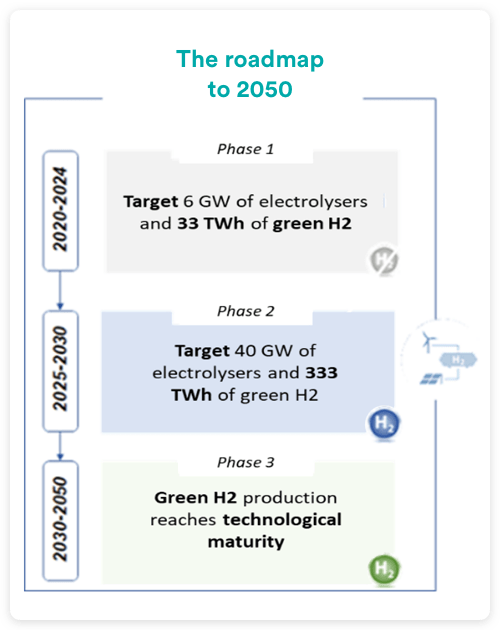

- A gradual transition from blue hydrogen to green hydrogen

- 40 GW of electrolyser capacity

- 333 TWh of green H2

In any case, green H2 is expected to reach technological maturity after 2030.

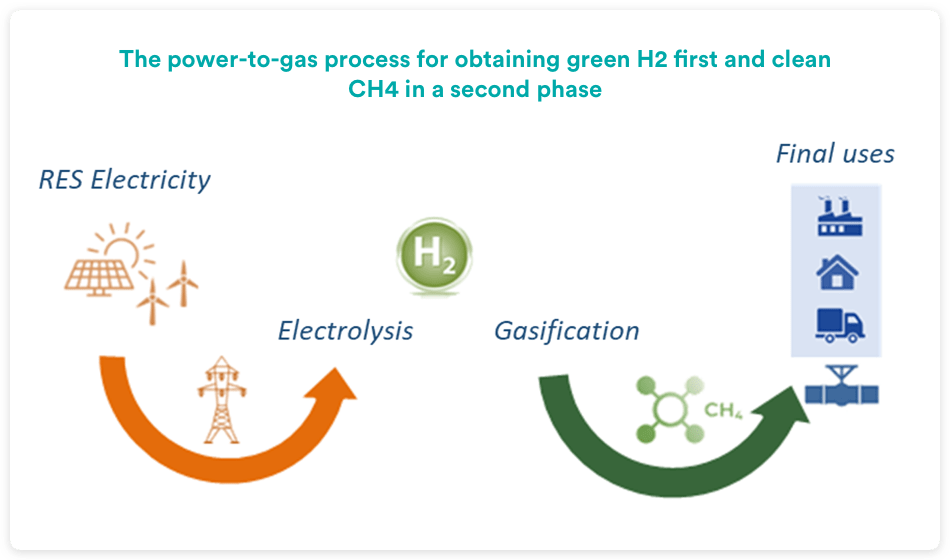

As regards future changes, sector coupling (i.e. investing in ways for the electricity and gas networks to communicate) and more specifically power to gas (P2G), are the most crucial challenge in developing hydrogen. P2G technology, using electrolysis, is able to transform excess renewable energy into storable renewable gas (green hydrogen or synthetic natural gas). This solution makes it possible to decarbonise some consumption while still ensuring the seasonal flexibility required by the national energy system.

Infrastructure investments in this area seem to be encouraged by the Commission. However, it has not yet been defined whether the assets for green H2 production and renewable gas storage will be regulated or market-based.

Awareness is also growing within Italy that in order to decarbonise some sectors that cannot be electrified (such as industry and heavy transport), currently powered by natural gas or fossil fuels, it will be necessary to develop a “clean gas” chain, i.e. biomethane and green H2, so as to gradually replace CH4 with low carbon-impact gases. In any case, it is understood that in these sectors, energy efficiency initiatives will also have to increase significantly.

Steps of progress at european level

The EU strategies published in July 2020 set out a path for integrating all clean energy carriers, including hydrogen, within the decarbonisation process. Three macro-phases of development have been identified for hydrogen.

Over the short term (2025 -> 2030), “blending” may be sufficient to accommodate an increased production of green gas, which can be introduced into the networks via the transport network. It may however subsequently become insufficient to meet decarbonisation targets.

Over the medium to long term (2030 -> 2040), this distribution will be accompanied by the gradual development of “full-hydrogen” networks that will emerge from the first “hard-to-abate” sites, i.e. industrial uses in which hydrogen is a non-substitutable element in achieving decarbonisation.

Over the long term (2040 -> 2050), full-hydrogen islands will start to interconnect and also involve the household market.

The Hera Group’s goal

Thanks to the Group’s nature as a multi-utility and its diversified business portfolio, intra-business synergies provide an opportunity and a competitive advantage for Hera. By making processes circular, the waste produced in one business area becomes a resource for another, in a win-win game that makes the Group’s performance unique.

In hydrogen production, an integrated operator such as Hera has significant advantages. Economically competitive and sustainable production becomes possible: in the electrolysis process, low-cost green energy from WtEs which is no longer incentivised can be used to separate water into hydrogen and oxygen. The oxygen released can be used in the waste water purification process in the water cycle (in which Hera is the 2nd largest operator in Italy), while the hydrogen produced can be stored or distributed to end customers through the gas distribution network (in which Hera ranks 3rd nationally), creating a renewable and environmentally harmless energy cycle.

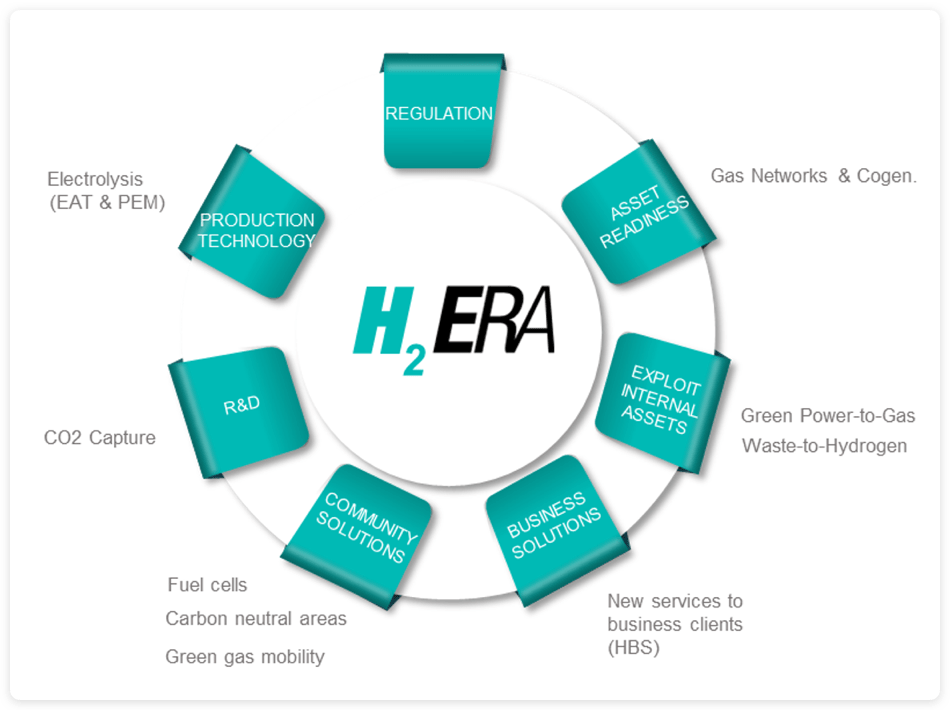

The Group’s strategy

The Group contributes to carbon neutrality through a series of actions designed to supply production sectors and communities with renewable and green energy. Since energy produced from renewable sources can be converted into electricity, but not all activities can be electrified, it is important to develop “green” fuels such as biomethane and hydrogen to promote decarbonisation.

Main areas of intervention and operation flows:

Research & Development, headed by the Innovation Central Department, which serves to verify the initial feasibility of the various initiatives. Once the analysis is complete, the projects are assigned to HERAtech for the following stages.

Impact analysis, concerning the effect that hydrogen will have on infrastructures in order to give shape to any necessary interventions, is being carried out by Inrete, Herambiente, HERAtech and Hera Comm.

Market analysis to identify potential buyers and their needs, is carried out by the Energy Management structure.

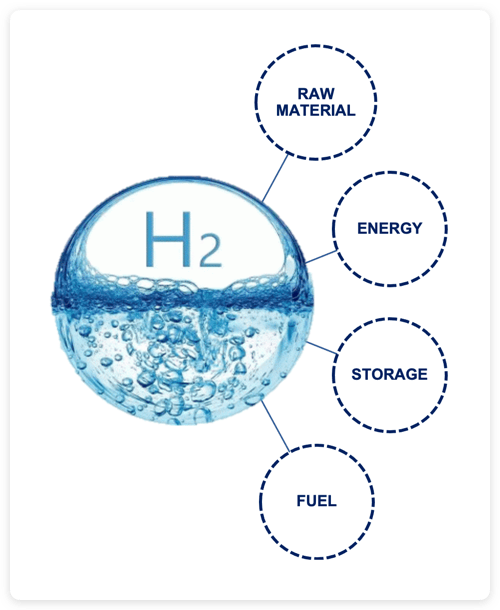

Areas and possible uses of hydrogen

-

Raw material: to produce fertilisers and in refinery processes

-

Energy: to produce fuel cells

-

Storage: for storage and later distribution via the gas network

-

Fuel: to fuel public and freight transport

Ongoing projects

Hydrogen as a raw material: waste to hydrogen

The goal:

To assess the feasibility of an experimental project to produce green, circular hydrogen to be used as a raw material for fertiliser production.

The project involves:

- use of renewable electricity produced by a WtE

- production of approximately 500 tonnes/year of hydrogen through the water electrolysis process

- incorporation of green, circular hydrogen into the fertiliser production process, which currently uses hydrogen from fossil fuels.

The competitive advantage:

The low-cost, and no longer incentivised, green energy from the Ferrara WTE plant will be used in the water electrolysis process. Furthermore, energy from the WTE plant has advantages over the green energy provided by photovoltaic plants: not only is it available for many hours a year, but it can also be constantly produced throughout the day.

Progress:

The Hera Group, Yara Italia (a leader in the production of nitrogen and complex fertilisers), and Sapio (a leading company in the field of technical and medicinal gases), have signed a memorandum to study the technological, economic and regulatory feasibility of a project to use renewable energy and develop the green hydrogen supply chain, which includes its generation, transport and subsequent use in the fertiliser production process.

In particular, the experimental hydrogen generation plant would use the renewable energy produced by Hera’s waste-to-energy plant in Ferrara, to produce hydrogen from water and supply the nearby Yara Italia industrial plant for fertiliser production. An assessment will be done concerning whether to locate the electrolysis plant at the WTE, providing for the transfer of hydrogen through a dedicated network or by road transport, or whether to locate it at the site of use.

Sapio is responsible for scouting plant technologies, and will also investigate further technical solutions for supplying the Yara plant.

Estimates predict an annual production capacity coming to 500 tonnes of green hydrogen.

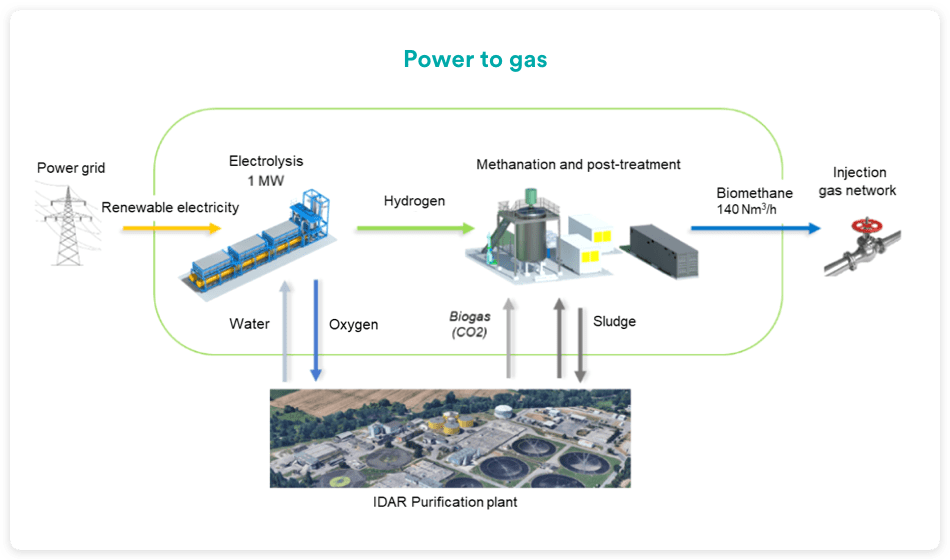

Hydrogen as storage: power to gas in the Bologna purification plant

The goal:

To set up a semi-industrial scale (1 MW) Power to Gas (P2G) demonstration methanation plant at the IDAR purification plant in Bologna to convert surplus renewable grid electricity into biomethane.

The project involves:

- installing a 1 MW electrolyser for producing hydrogen through water electrolysis

- constructing a biological methanation plant, for converting H2 and CO2 into biomethane

- injecting biomethane, more than 96% methane, into the natural gas distribution network.

The competitive advantage:

Excess non-storable green energy and wastewater, treated in the adjacent purification plant, will be fed into the electrolyser to produce hydrogen, which will be injected into the gas distribution network, after being transformed into methane through the methanation process that converts the carbon dioxide present in the biogas produced by the anaerobic digestion plant found in the purifier. As regards circularity, while the oxygen produced by electrolysis will be reused in the wastewater treatment process, the sewage sludge will be used to feed the methanation reactor in a continuous and mutually integrated process.

Progress:

The project calls for a collaboration between several of Hera’s business units. More specifically, at Hera’s purifier in Bologna Corticella, an innovative plant is at an advanced stage of design that will allow excess renewable electricity to be transformed into “green” hydrogen. This will in turn be fed into the networks, by using the purified water and returning oxygen, biogas and sludge to the water purification process, to obtain a mutually beneficial “symbiosis” between the two plants, with an additional environmental benefit.

Preliminary tests have been carried out on sewage sludge and biogas from the IDAR plant to verify their compatibility with biological methanation processes. Possible plant configurations and renewable electricity purchase scenarios have also been identified, as well as possible suppliers of electrolysis systems. After identifying the area in which to locate the pilot plant within IDAR, Heratech has ascertained that the plant’s location is compatible with the content of the Seveso directive, and the construction authorisation procedure is due to begin shortly. The plant is expected to become operational in late 2023.

Hydrogen as a source of energy: positive energy districts

The goal:

To define innovative and replicable solutions for positive energy districts and neighbourhoods (PEDN), by integrating innovative technologies.

The project involves:

- experimental temporary supply of a portion of the distribution network with mixtures of hydrogen and methane, with gradually increasing percentages, up to 10% hydrogen

- use of hydrogen to accumulate the energy produced by photovoltaic panels during the day and make it available at night as electricity, through a fuel cell, possibly coupled with an electric battery to ensure the district’s energy autonomy.

The competitive advantage:

The Hydrogen Valley model refers to a geographical area (city, district, industrial cluster, etc.) in which different technological applications are combined in an integrated ecosystem, to improve the energy economy underlying the project. The energy produced by the photovoltaic panels during the day, which would otherwise be wasted, will be converted into hydrogen and then stored in a special fuel cell to be available at night in the form of electricity, thus ensuring 100% green energy autonomy for the district.

Progress:

A portion of the Modena distribution network (approximately 60 users) is expected to be supplied, temporarily and experimentally, with mixtures of hydrogen and methane having gradually increasing percentages, up to 10% hydrogen.

The supply tests will be accompanied by control activities, some taking place in the laboratory, before, during and after the experiments in order to identify any impact of the injections on the existing distribution infrastructures, on the management methods in use and on the gas user systems of the end customers served.

Hydrogen as fuel: sustainable public transportation

The goal:

To produce green hydrogen from photovoltaic sources and to construct a refuelling station to supply buses for local public transport with hydrogen.

The project involves:

- installing photovoltaic panels on bus shelters and building roofs

- converting electricity produced on-site into hydrogen, and distributing it via a refuelling station for buses in the local transportation network.

The competitive advantage:

The electrolysis plant will be powered mainly by renewable electricity, produced by photovoltaic installations on the roofs of buildings belonging to the local transportation company and on new shelters to be built, covering the bus parking area.

Progress:

In June 2021, the Municipality of Ravenna, the Hera Group, Ravenna Holding, Start Romagna and Aess signed a memorandum to assess the feasibility of an experimental programme for developing a green hydrogen supply chain, to be used mainly, but not exclusively, by local public transportation in the Municipality of Ravenna.

In particular, the project studies the construction of a plant for producing green hydrogen through electrolysis. The plant will probably be located in an area owned by Ravenna Holding, where a storage facility for the hydrogen produced will also be constructed, along with a distributor to supply the new hydrogen-powered public transportation vehicles that Start Romagna, the local public transportation company, intends to purchase.

In order to sustainably fuel hydrogen production, the project foresees the production of renewable electricity, thanks to photovoltaic systems installed on the roofs available on the buildings in the area and on new shelters to be built over the bus parking area.

Hydrogen in energy distribution: asset readiness

The goal:

To assess the impact of hydrogen blending and to obtain short-term environmental externalities.

The project calls for two phases:

- first phase: carrying out a field test with increasing concentrations of hydrogen (2%-10%) in the household distribution network

- second phase: introducing small percentages of hydrogen (1%-2%) into the city distribution network.

The competitive advantage:

Hydrogen blending know-how makes it possible to plan investments in upgrading and repurposing. It allows suppliers with compatible materials to be selected, and the impacts of blended distribution networks to be understood, including:

- impact on odorization

- impact on flame colour

- confirmation of the effects of stratification in the pipeline

- impact on road leak detection devices

- impact on gas distribution devices (meters, junctions, reducers, etc.)

- impact on the functions of domestic gas appliances and potential quantification of adaptation costs

- identification of additional needs and currently existing barriers to authorisation for hydrogen emission

- identification of technical gaps hindering regulatory updating.

The main manufacturers of gas distribution devices and of household gas appliances will participate in this project. The results will be certified by a specialised firm.

The long-awaited changes in gas quality (updating technical regulations on gas quality, reaching 2% input) open the way for a systematic and continuous injection of H2NG into urban distribution networks. This will make it possible to start decarbonisation in urban thermal uses in a short period of time, without having to wait for upgrading in internal systems in buildings and therefore irrespective of the perception and economic resources of individual citizens.