In good waters

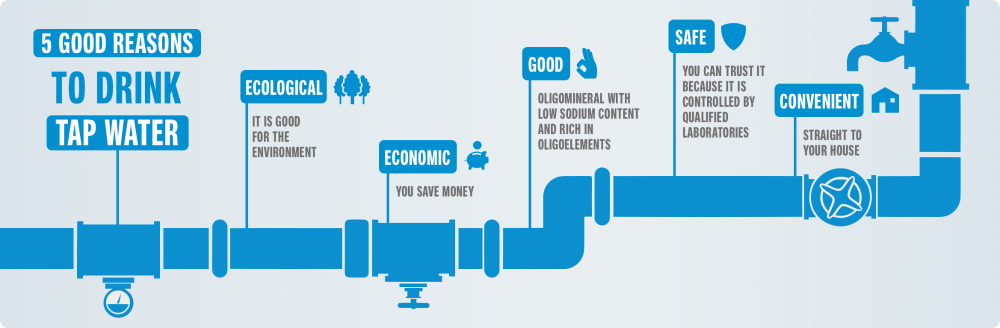

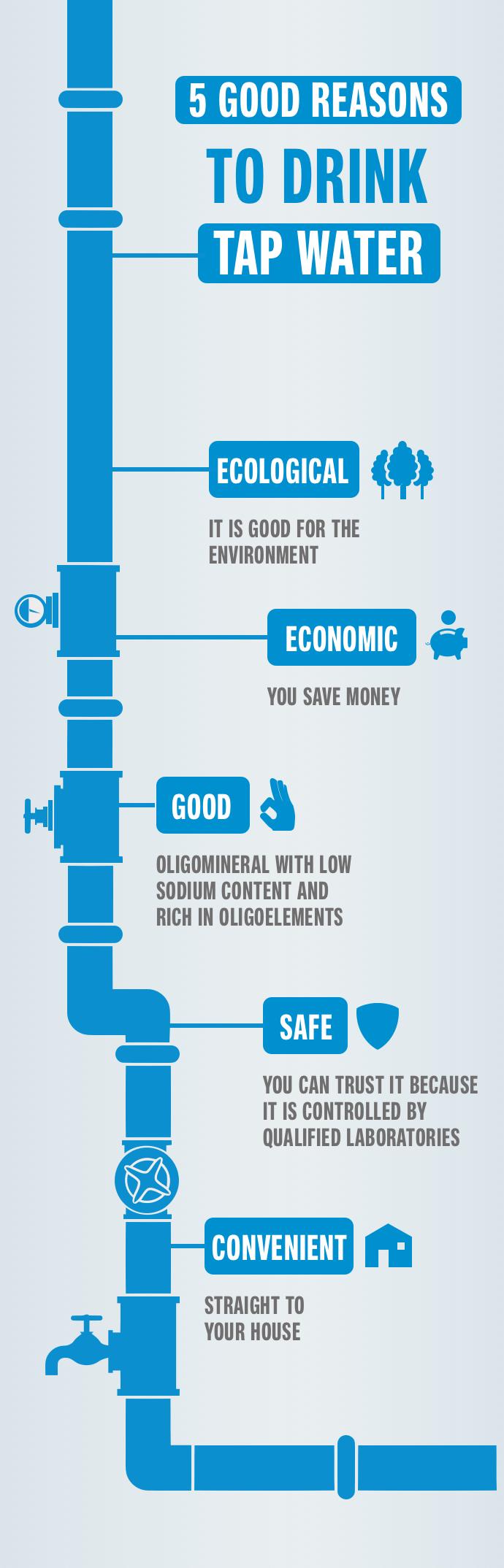

This report is dedicated to the quality of the zero-km water that Hera distributes in the served territories, and wants to reassure stakeholders that it is safe and good to drink and that it has nothing to envy compared to bottled mineral water...

...also, it is cheap and saves you money

In fact, a family of 3 can save up to 460 euros per year by using tap water instead of bottled water.

Asset Publisher

Hera invests for an increasingly safe and affordable water supply

In 2020, we invested 166.1 million euros in water cycle. Investments in Hera Group’s territory are about 30% higher than the Italian average.

The identity card of the water service and Hera's key figures

Hera Group manages all the phases necessary to make water available and usable for civil and industrial use and consumption in an integrated way.

Where does the water we drink come from

Hera draws water from different sources: surface water (streams, rivers, and lakes), groundwater mainly in the plains, and springs located in hills and mountains.

The controls to be... in good water

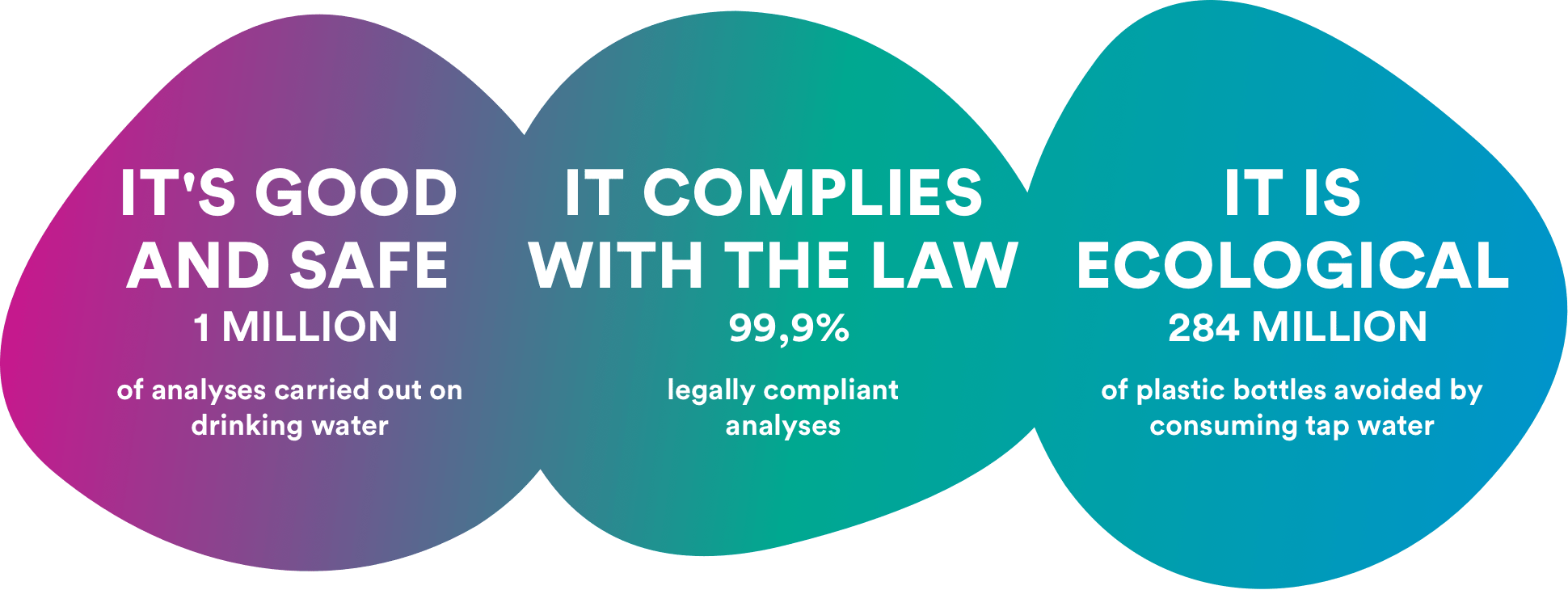

We guarantee water to be good and safe to drink, in compliance with regulatory requirements and with careful monitoring throughout the production chain.

Preferring tap water generates economic and environmental benefits

Tap water is good for the environment! 51% of customers drink tap water avoiding about 284 million plastic bottles.